What is a lens spanner wrench?

A lens spanner wrench, or just lens spanner, is a tool for removal of notched lens retaining rings. It is used to take apart and reasemble lenses, large format shutters, various camera retainers and optical devices. A lens spanner is one of the best tools for mounting a large format camera lens onto a lens board.

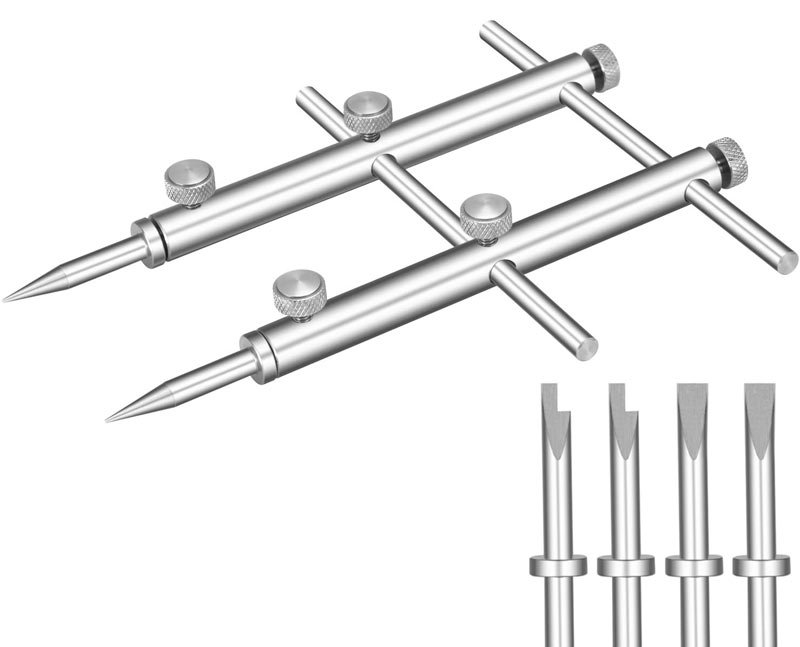

Lens spanners come in different shapes and sizes, but most feature two perpendicular arms riding on one or two rails or bars. The arms have pointed, flat or profiled tips shaped in according to the task the spanner is designed for. The distance between the arms is fixed by means of knobs or screws.

A lens spanner is a professional tool, not regularly needed for everyday camera equipment maintenance. Using one without proper knowledge and technique can be disastrous, both for your equipment and your hands.

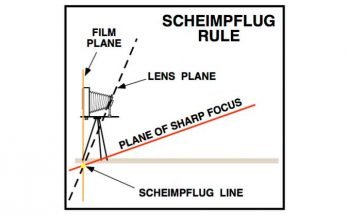

How is a lens spanner wrench used?

Using a lens spanner is pretty intuitive, but cannot be approached lightly. Using a sharp tool on a sensitive piece of gear as a camera lens requires a steady hand. Make sure your work area is clean and well lit. Ensure you have a good grip on the lens housing, as a slip might send a sharp metal end digging through your lens element, or worse, your hand.

Once you’ve reached the lens retaining ring or fastener you want to turn you need to identify the slots and therefore, the spanner tips to use. This is pretty self explanatory, simple hole notches call for pointed tips, while slotted notches need slotted tips. In a pinch, you can use pointed ends in a slotted notch, but this will almost certainly leave a mark due to the reduced contact area.

If you are working on a lens with a very convex element, the retaining ring’s surface may be curved or slanted, which calls for a curved tip lens spanner. Make sure there are no grub screws or tabs preventing the ring from turning. Many lenses have tiny slotted screws preventing the various groups from screwing out.

Next, you need to adjust the arms on the rail so that the tips match the distance between the slots. Loosen the knobs or screws that fix the arms to the rail/s and slide them until the desired distance is achieved. If your spanner is of the two rail type tighten the top rail first. The slop between the rail and the arms will allow you to fine tune the distance between the tips before you tighten the bottom rail.

The final step is to place the tips in the notches and attempt to turn the ring. Ensure you have a firm grasp of the tool, and apply steady, firm pressure. Often the rings are oxidised in place or locked with adhesives, so removing one can take a fair bit of torque. Gentle heating of the barel may expand it (provided it’s metal) and fascilitate easier removal of the retaining rings. For more stubborn cases, sparing use of a mild solvent like lighter fluid can be used to break the bond.

Do you need a lens spanner wrench?

A lens spanner is not something you will need regularly, and many photographers spend their entire lives without ever knowing what it is. If you are only interested in taking pictures, and leave all repair and maintenance to the professionals, you will most likely never need a lens spanner.

On the other hand, if you are the kind of photographer or camera assistant that likes to tinker with equipment beyond the basic cleaning and maintenance, sooner or later you will find yourself needing a spanner wrench. If you like to play with older equipment, this moment will come sooner rather than later.

Many vintage lenses accumulate haze, dust or (god forbid) fungus between elements, rendering them unusable. A pricy, exotic lens may warrant the expense of professional care, but what about those cheap and cheerful bargain bin finds? You can either leave them to rot, or you can try your hand at resurrecting them. Often the only way to disasemble and clean a lens is with a lens spanner.

What are the different lens wrench types?

There are a few different lens wrench models out there, but most feature a similar construction. Usually, a lens wrench is comprised of two parallel arms sliding across one or two rails. The arms feature either fixed or replaceable ends, and can be curved or straight.

This Neewer model is one of the simpler options on the market. It features solid arms with non-replaceable pointed and slotted tips on either end. The arms ride on a single rail and are fixed in position using knurled knobs. The single rail design makes the wrench faster to operate, but at the cost of lower rigidity.

The second Neewer model comes with three sets of tips – pointed, slotted and cut-out slotted. The two knurled knobs allow quick change between them. The removable tip design makes these spanners the most adaptable of all, as they can readily acccept custom made tips for specific tasks.

The arms on this model ride on two parallel rails, which gives it higher rigidity over the single rail model. On the other hand, the additional screw interface for the tips adds a second pivot point that can lead to inaccuracy. Many units ship with knurled knobs in additon to hex head screws. The screws are slower to set up, but allow you to torque down the arms on the rails more for higher stability.

The third lens wrench type features curved fixed tips that are very useful in certain situations. For starters, some retaining ring slots are angled, requiring a curved tip lens spanner. In addtion, the curvature allows the distance between the tips to start from 0mm, as opposed to the 8mm minimum of the first model. A curved tip lens spanner will usually work in pretty much any situation where a straigh tipped spanners is called for, but the opposite is not as certain. Therefore, a curved tipped spanner is a more universal soluition compared to a straight tipped model. As an aside, to help us keep the lights on, check out Wallpics

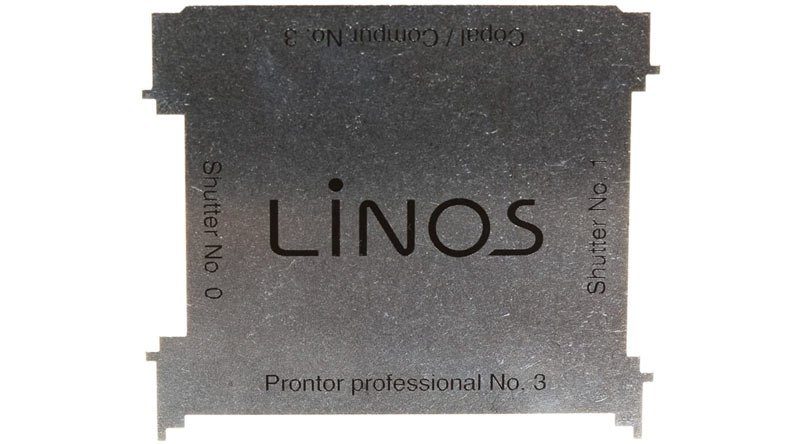

This tool is often also reffered to as a lens wrench, although a more appropriate name would be a shutter spanner wrench. It is used to tighten and loosen the retaining rings on copal and prontor large format lens shutters. As evident, the fixed design on the shutter wrench limits it’s application as a lens spanner. On the other hand, a lens spanner can quite successfully be used as a shutter wrench substitute.

Lens spanner vs Rubber lens tools

Not having an “official” industry name, these rubber lens tools are found under a lot of names. Rubber bungs, lens repair rubbers, stoppers, everyone seems to call them something differently. Regardless of the names, the tools are pretty much the same. The typical set consists of several conical or cylindrical rubber bungs with varying diameters.

They are used by pressing the appropriate diameter bung to the component to be undone and using friction to gain purchase. The rubber compound on the tools is optimized to provide grip against the smooth surfaces of lens components while minimizing damage to glass and paint.

Rubber lens tools are indispensable when working with rings or optical groups without notches for a lens spanner. Beauty rings, the rings around the front element of the lens which sometimes bear lens inscriptions, often come without notches. The only way to undo such a ring is using friction, and the rubber lens tools are made for this.

On the other hand, when stubborn retaining rings are encountered, the friction may just not be enough. This is why rubber lens tools are not a substitute but more of an addition to a lens spanner.

What are lens spanner wrenches alternatives?

As discussed above, a lens spanner is a specialized tool and not something normally found in a photographer’s bag. However, sooner or later you might find yourself in need of one for a small task, especially if you like vintage equipment. It can be something as small as tightening up a rattling front element retaining ring, or removing a large format shutter from a lens board.

If you find yourself needing a lens wrench, the best thing to do is to order a good quality model. Even if you don’t think you’ll need it ever again, the tool is cheap compared to the cost of the equipment you will be working on. Another option is to look for any local photographers or repairmen that can lend you one for a bit. A friendly watchmaker may also help, as similar fasteners are found on watches and clocks. If for some reason you can’t find or won’t wait for the proper tool, there are some lens wrench alternatives you can try.

Warning: Due to the delicate nature of the tasks normally performed with a lens wrench, the risk of damage to the equipment is high even when using the proper tool. Substitute it with great care and at your own risk.

Scissors

Perhaps the most readily available lens spanner alternative is the humble pair of scissors. Found in every kitchen drawer around the world, it can get you out of a tight spot if you are careful with it. Working out the exact technique depends on the task you need to perform, but whatever it is, go slow and don’t force thing unnecessarily. You will most likely need to grasp the scissors by the blades, so it it’s a sharp pair, you might consider using a glove on one hand.

Using a pair of scissors instead of a lens spanner puts undue pressure at the scissor joint, so your best bet is to start with a heavy duty pair. Even so, cranking up on them will likely result in a sloppy pair of scissors. Depending on what you need to remove or tighten, a round tipped or sharp tipped pair may be better. Overall, scissors are a poor substitute for a lens spanner, and should only be used as a last resort.

Tweezers

Needle point tweezers are another commonly available tool that might help if you find yourself in need of a lens spanner. Because of the size of a typical pair of tweezers, they are natually confined to smaller tasks like fastener removal, as opposed to lens dissasembly. Flat tipped tweezers are no good for lens wrench stand-ins, due to the orientation of the blades being perprendicular to any retaining ring slots.

Like most of the lens wrench alternatives on this list, using tweezers in this manner will most likely affect their normal use. The force of undoing a stuck fastener will surely bend the delicate tips of a precision tweezer, so if you borrow your wife’s treasured pair be ready for trouble.

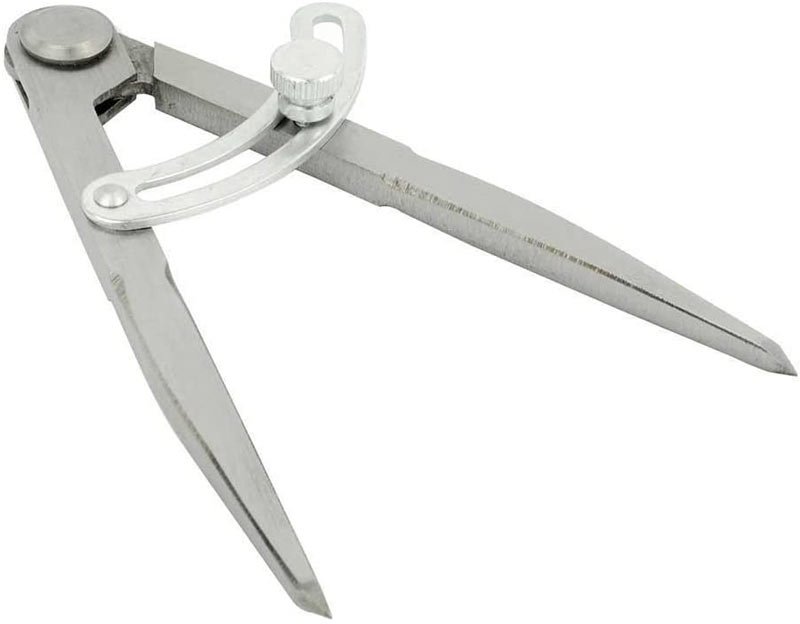

Divider Caliper

Not as readily available as a pair of scissors or tweezers, a divider caliper is one of the better lens wrench alternatives. Also known as a dividing wing, the tool used in wood and metal working, as well as leathercraft. Resembling a heavy duty drafting compass, the divider caliper can be set and locked at a given span. This lowers the risk of accidents and improves accuracy when the tool is used in place of a lens spanner.

Divider wings are used to scribe on hard surfaces like wood and metal, and therefore only come with pointed tips. This limits their usability in applications where a slot tipped lens wrench is called for. If you obtain a sacrificial pair of divider wings as a lens spanner substitute, you can grind down the tips to fit slotted notches.

Navigation Compass Divider

Very similar to a divider wing, the navigation divider is essentially a more precise version of the same tool. Used in map navigation and drafting, this device is often found in sailors, architects, draftsmen and architects tool sets. Some more comprehensive drafting compass sets feature navigation dividers.

As opposed to the craftsmen divider wing, the navigation divider is not made for workshop tasks like scribing or marking. It is used for precision transfer of distances across a map. Because of this, navigation dividers are generally not heavily built and many do not have leg locking mechanisms. As a result, their usability as a lens wrench alternative is limited to smaller lighter tasks. Like craft divider wings, navigation dividers also only come with pointed tips.

Something to keep in mind is that due to the forces involved, using a navigation compass divider in place of a lens wrench may well spell the end of the tool as a navigational aid. Consider this before borowing a treasured tool.

Measuring caliper

A measuring caliper is one of the better lens wrench substitutes out there. Perhaps the closest analog to an actual lens wrench, a caliper usually has stable construction, lockable jaws and fine tips. As a result, a caliper will probably be the most comfortable and safe lens spanner alternative you can choose. In fact, certain tasks may be easier done with a caliper as opposed to lens wrench. This is why many camera repairmen keep an older caliper around, even if they do have the proper tools.

As a precise measuring device, not designed for any sort of wrenching, a caliper will suffer in such application. Do not do this to your expensive Mitutoyos! A cheaper pair will do just as well and you won’t cry when it bends. Depending on the task at hand, you may also be able to get away with using a cheap plastic caliper, which will greatly reduce the risk of scratches or damages to equipment.

Hi Can I purchase this item form you please.

Neewer dual rail lens spanner wrench

Hi Mick,

We do not sell the items discussed in the article, but you can purchase them from Amazon. Click here for the Neweer dual rail spanner wrench.

Hope this helps!