So, you’ve embarked on an exciting darkroom printing journey, but you’re faced with a tough decision right at the checkout of your supplies order. Do you choose resin coated (RC) or fiber based (FB) photographic paper? If you dig around, you will find endless debates on forums regarding the merits ot both types. However, the choice does not have to be complicated, as it all boils down to a few simple differences.

Both RC and FB enlarging papers have their rightful place in the modern darkroom, but they are generally used for slightly different purposes. Once you’ve discovered what the main advantages and drawbacks of each kind is, you can make an informed decision and get the best out of your work. For starters, let’s have a look at the structure of each type and the advantages and drawbacks they carry.

The basics

Let’s get started with the simple fact that pretty much all modern darkroom printing papers are capable of outstanding results. The emulsion characteristics of fiber based and resin coated materials of comparable product lines within the same manufacturer are virtually identical. In essence, you will be able to obtain a similar tonal range and detail from both FB and RC papers.

Any difference in the look of both types of paper comes from the structure of the paper and the way emulsion is incorporated onto its surface. With a skillful printer at work, it takes a keen eye to spot the difference. For example, Ilford’s highly acclaimed Multigrade range of papers comes in both resin coated and fiber based varieties. Only a highly experienced printer will be able to tell which is which in a framed exhibition print.

So what is the main difference then? It’s simple and it lies in the names of both types of printing paper.

Fiber based

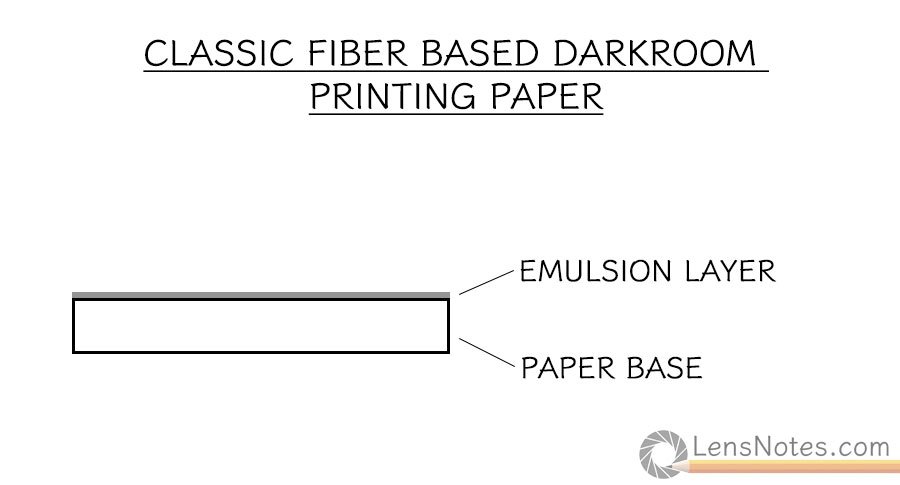

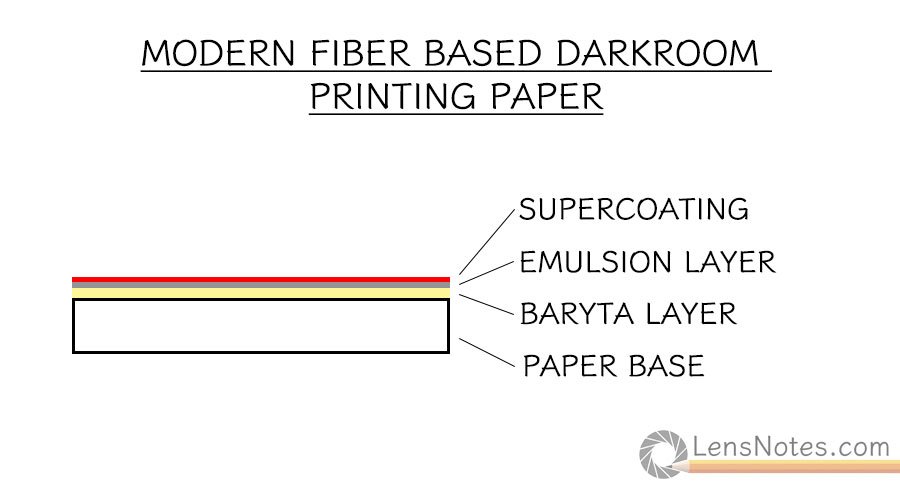

Fiber based photographic paper is the older type of the two, in fact the first commercially produced darkroom printing papers were of this type. In it’s simplest form, FB darkroom paper is comprised of a typically heavy (225gsm or more) paper base onto which the silver-gelatin emulsion is coated. However, it was found early on that the direct coating of the emulsion onto the paper base, had its issues. Most often, it resulted in impurities in the paper base interfering with the emulsion. To prevent this, enlarging paper manufacturers introduced an intermediary layer, that is nowadays known as the baryta layer. All currently produced fiber based enlarging paper incorporates a baryta layer.

The baryta layer is typically comprised of barium and strontium sulfates. It not only isolates the silver-gelatin emulsion from the paper base, but provides brightening through it’s higher light reflection index. In addition, the baryta layer can be tinted to produce specialist warmtone or cooltone papers.

Because the baryta layer and the emulsion are coated directly onto the bare paper base, they are ingrained into the paper fibers. This brings out texture in the emulsion and many photographers feel it contributes to the sense of depth ot the printed image. According to popular opinion, fiber based photographic paper is the gold standard for archival quality exhibition prints. Simply put, a finished, processed fiber based print consists only of paper, gelatin, metallic silver and the inert baryta layer. All of these components have proven to be long lasting under the right conditions.

The exposed paper base, however, is also also what makes FB darkroom paper a lot harder to work with. Wet fiber based paper is rather fragile, and emulsion can easily lift off the base with prolonged wet time. In processing, the paper base quickly absorbs chemicals, which then requires lengthy washing and careful drying. As it dries, fiber based enlarging paper inevitably curls, which necessitates various mounting or flattening techniques. Resin coated paper was developed to solve these issues, but had problems of it’s own, especially in the early days. As a result, both types of paper now coexist, catering to slightly different purposes.

Resin coated

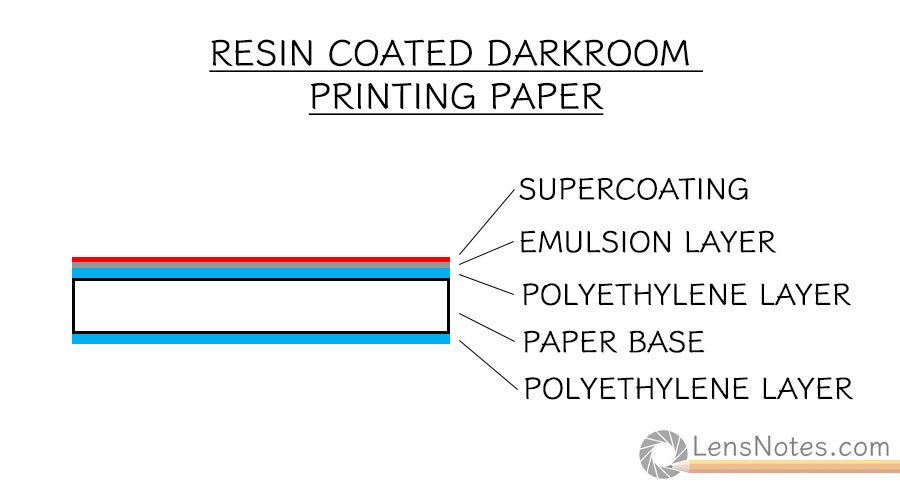

Compared to fiber based paper, resin coated materials are relatively newer, having been introduced in the 1940s but not widely adopted until after WWII. The RC base is comprised of paper sealed between two waterproofing (resin) layers, typically polyethylene. The silver-gelatin emulsion is coated onto this base similarly to the way it is on FB papers, but a baryta layer is not used here. Any brightening or tinting agents are incorporated into the inner polyethylene lamination layer or the emulsion itself. The lamination process significantly strenghtens the base, and as a result, RC paper is a lot tougher and durable than fiber based. In addition, all RC papers come with a hardened gelatine supercoating.

Because the base of RC paper does not absorb water or chemicals during processing, developing and washing routines for it are closer to those of film than those of FB paper. Whereas fiber prints may require up to an hour wash, resin coated is happy with as little as a few minutes. You are only washing the relatively thin emulsion layer, which can absorb only a very tiny amount of chemistry. In addition, resin coated paper is just as tough when wet as it is dry, which helps prevent damage in processing and makes it easier to work with. The laminated base also fascilitates quick dry times, and gives RC paper one of it’s most important advantages – flatness.

Compare and contrast

Now you have an idea of the physical differences between the two kinds of darkroom paper, let’s what they mean in terms of real life characteristics.

Ease of use

Perhaps the single biggest difference between resin coated and fiber based darkroom printing papers is ease of use. It’s no coincidence that all beginner courses start with RC paper. For starters, resin coated paper is a lot more durable when wet, so the chances of a clumsy grab with the tongs tearing or gouging the print are minimal. Because the RC print does not absorb any chemistry, carryover is minimal and as a result, processing chemicals tend to last longer. Furthermore, you can also get away with using water instead of a stop bath, as you are not fighting with the large amounts or developer a fiber based print would soak up. Finally, RC paper wash routines are a lot less rigorous, and even a brief soak in clean water can yield a satisfactory result.

Fiber based photo paper, on the other hand, is a bit more involved. Whereas the basics are the same, to obtain a decent result you need to be a lot more steadfast with your technique and routines. An RC print is typically developed within a minute, while a fiber based sheet may require up to three. The dry sheet you plop into the developer tray can soak up a considerable amount of developer. A stop bath is necessary to ensure consistency and to prevent the developer carryover from ruining your fixer. Once fixed, you have the choice of a lenghty (up to 60 minutes for double weight paper) wash in running water, or a 10 min soak in hypo clearing agent and a 30 min wash.

Prestige

Directly resulting from the user-friendly nature of RC paper, fiber based is often touted as the superior medium of the masters. Due it’s temperamental nature and the fact that it’s proper processing requires a lot more time, effort and resources, FB photographic paper use is often a point of pride for photographers. There are certain circles where anything resin coated is frowned upon and shunned as inferior.

Eco friendliness

Even though various conservation techniques and routines are employed, the fact is that properly processing and finishing a fiber based print to archival standards is a lengthy and resource intensive endeavor. Ilford, for example, suggest a 5 minute running water wash, followed by 10 minutes in hypo clearing agent, followed by another 5 minutes in fresh running water. Furthermore, in their “Ilford Optimum Permanence Wash Sequence With Selenium Toner” they recommend treating fiber prints to a final wash of 30 minutes in running water. Depending on your workflow, print size and output, this can easily convert into a few gallons of freshwater down the drain per printing session.

In contrast, Ilford suggest that as little as 30 seconds vigorous washing in fresh water is sufficient for resin coated prints. Consequently, good washing of resin coated paper can easily be achieved even in a darkroom with no running water or sewer connection, with just a few swaps of water in the tray. Actually, shorter wash time is one of the key reasons behind the development of RC photo papers. In addition, resin coated prints require no wash aid, further reducing the chemicals and water waste involved in the process. If you are concerned about the environmental impact of your photography practice, or live in an area with water shortages, consider the advantages of resin coated materials.

Drying time & Flatness

Anyone who has ever printed with fiber based paper (or even just handled an unmounted print) can attest to the curly nature it has. Drying fiber paper so that it stays relatively flat requires carefull drying technique or the use of tools such as blotter books. Even a carefully flattened FB print will curl given a little wiggle room and humidity. To prevent this, complicated framing and mounting procedures are needed, some of which are outside the realm of hobby printers.

Resin coated paper, on the other hand, dries completely flat and stays flat through thick and thin. Consequently, the prints are much easier and cheaper to store, frame and exhibit. Faster drying and dimensional stability are enough for some printers to work exclusively with these materials.

Durability

Ask any darkroom printer, and they will tell you, resin coated paper is tough. If you don’t believe me, try and tear an RC print. The polyethylene lamination of the base makes these prints nearly indestructable. In addition, getting a resin coated print wet is no big deal. Water will not affect any of it physical properties, unless the print is submerged for prolonged periods, in which case water can start getting into the base from the edges. In any case, getting a fiber based print wet can be a lot more disastrous, a lot quicker than an RC.

The one vulnerability resin waterproofing presents is a reduced tolerance to heat compared to FB paper. As with most plastics, polyethylene will not fare well when subjected to excessive temperatures, but then again, neither will fiber if you are persistent enough. Basically, the one area where resin coated enlarging paper is unanimously favoured is for prints that will be manually handled or abused in any way.

Surface quality

As discussed above, the main visual difference between fiber based and resin coated papers is surface quality. Because the emulsion is coated on the bare base (with the baryta layer ground), FB darkroom prints tend to have a richer, more organic texture. Resin coated papers, on the other hand, have smooth flawless base. The resin layer upon which the emulsion is coated can be embossed in manufacturing to create matt or pearl texture, of left smooth for a glossy finish.

Basically, the way you approach surface quality depends on whether you choose RC or FB. With resin coated papers, you have very little control over surface quality beyond the initial decision of finish you choose when purchasing the paper. With fiber based, on the other hand, there are ways to change the finish in the drying stage. In fact, the only way to achieve high-gloss finish on an fiber based print is through a special glazing dryer. Even with Glossy fiber based paper, if you simply air dry the print you will get a result comparable to the Pearl RC paper finish.

Archival properties

Archival properties are perhaps the most controversial aspect of the FB vs RC debate. Resin coated materials have long suffered from bad reputation regarding their archival properties. Issues with early iterations included delamination of the resin layers, chemical ingress from the edges or accelerated aging. Staining and cracking of the emulsion or the polyethylene base were also observed, all resulting in the prevaling opinion that resin coated paper is not suitable for archival purposes.

Even though RC photo paper has gone a long way since these days, the reputation lingers. This also stems from the fact that resin coated photographic materials are a moder, high tech product with a lot of components, many of which have simply not stood the test of time yet. Compare that to fiber based, a centuries old technollogy, and you can see where the prejudice comes from. From the mouth of the horse itself (Ilford): “If long-term archival stability is your primary requirement, we recommend fibre base papers as the medium of choice.”

Fiber based darkroom printing paper has long been, and still remains, the gold standard in photographic printing, especially where long term archival properties are sought after. It’s tried and tested, and even though it’s undergone significant development, the basic components are the same. A common belief amongst photographic conservationists is that due to the porous nature of the FB print base, it is able to wick any airbourne pollutants out of the emulsion before staining and oxidation occurs. The emulsion on resin coated prints, on the other hand, has to rely on proprietary antioxidants and the longevity of those is anyone’s guess.

In the end, regardless of your personal stance on the issue, you have to consider the broader consensus. If you are making your prints with the hopes of getting them into a major institution, the fact is that they will stand a better chance on a fiber base.

Toning

Sooner or later in your darkroom printing journey, you will get to the topic of further image manipulation, most commonly toning. Apart from aesthetic purposes, treatment with certain toners like selenium or gold is often employed as means to further improve the archival properties of a print.

Generally, the porous nature of fiber based paper lends itself to chemical manipulations much more readily than resin coated, although both types take toning well. The emulsion is the top layer for all papers (apart from any protective supercoating), so the base makes no difference to the toning action. Resin coated and fiber based papers do react differently to toning. If you use both, do not rely on toning results being transferable across them.

In addition, advanced toning techniques are mostly used by experienced printers who tend to work with fiber based paper. Consequently, it will be much easier to find information on these processes for fiber based printing than it is for resin coated.

Cost

Last but not least, cost can be a big factor when choosing the type of photographic paper you use. Typically, resin coated papers tend to be more affordable than fiber based options of comparable characteristics and size. For example, currently a 100 sheet packet of Ilford Multigrade IV FB Fiber Based Variable Contrast Double Weight paper in 10×8 size costs about 30% more than a pack of Ilford Multigrade IV RC Deluxe Resin Coated VC Paper. But material cost does not tell the whole story.

As discussed earlier, fiber based paper requires a more comprehensive and rigorous processing routine, and this inevitably translates into money. If you are printing in a rental darkroom, for example, the extended washing and drying times of FB paper may mean you need to budget for a couple of extra hours for each printing session. Even if you print in your own darkroom and are not time limited, switching from FB to RC photo paper will most certainly increase your utilities and chemical bills. We’ve already covered the environmental aspect of the extended washing that fiber based prints require, but do not forget the monetary side too.

Fiber based paper is harder on chemicals, and many solutions have lower capacity when working with FB. In addition, whereas RC paper can successfully be processed with just developer and fixer, FB is not modest. For a good FB workflow, you will also need stop bath and a hypo clearing agent, in addition to any toning or other manipulations you may require. Naturally, these extra solutions need trays to reside in, which in turn need space. If you are printing in a small, makeshift darkroom, it can quickly get tight.

Finally, working with fiber based materials may require additional equipment not normally used for RC printing. Apart from the increased number of trays and tongs needed for the larger number of chemical solutions, there are other necessities. For example, while you can successfully wash a stack of RC 8x10s in just a tray of water, archival processing of FB prints is not so simple. Unless you can comit to a lenghty, manual procedure of swapping prints from tray to tray, changing water and agitating, you will be needing a (somewhat) automated washing method. This can be a tray cascade, a tray syphon or a full blown archival washer.

If you are working in a community darkroom with several or many people printing concurrently, save yourself the misery of attempting to use FB paper; your cohorts inevitably forget, wash things for you inappropriately, transfer your prints into the slow soak bath from the constant flow bath, drop other prints such that the edges hit your gel layer, and may even attempt to dry your prints to get them out of the way. I have experience these things, and in a group setting would now only use RC paper. However, I’ve been happy using the same available baths and trays, as long as the solutions were fresh and appropriate, the same slow rinse with slight agitation, etc. when I was the sole person in the darkroom and had some FB paper. Then, I also had to remember that I was looking at different times, that my recorded data for the particular enlarger with RC was nearly useless for FB, so I needed new test strips anyway. More time, and perhaps, when I would get more accomplished and proficient, then better prints?

Thank you for this informative article. I remember when I started printing in the high school darkroom in the late 1970’s I used FB papers. When I started in my own darkroom in the mid 1980’s I chose to use RC papers because of the reasons you mentioned in your fine article. Now in 2021 I am building my third dedicated photo lab and will be going back to FB papers for the fine results I remember from high school. It just seemed like my printing quality went down when I switched to RC papers. I could not put my finger on what was wrong, your article made the reason very clear.

Good morning to all…

I have been photographing for more years than I care to admit, and at some time I decided to shift from fiber-based to resin-coated “paper” for immensely practical reasons… all of which you document perfectly in this article.

I often found that the type of paper was of the utmost importance in galleries, and I had little to no patience with this.

My objective has always been to produce brilliant (contrast of course) prints with as much grain as I could produce when I wanted to; in other words an element of three-dimensionality. At the time I used Agfa multi-contrast paper and was very happy with it.

To me, asking a photographer which paper he used made as much sense as asking a painter which make of canvas he uses (I also draw and paint). Of course the photograph has to survive in the world over time, but the chances of doing this effectively are far greater with resin-coated, than with fiber-based paper.

Now I’d like to re-enter the (real) photographic world, and assemble a list of suppliers from whom I can buy materials. Does anyone have some ideas about this?

Roberts Camera or BH Photo for Ilford products. Freestyle Photo in LA for chemicals and special equipment. Photographer’s Formulary is excellent for raw chemicals to mix your own. Top notch.

Recent progress in resin coated papers have yielded papers with highly archival properties, even when compared to fiber.

I honestly only use heavy weighted rc paper from ilford now because they are proving, through modern science, that these papers will stand the test of time just like fiber will.

Even inkjet papers are archival over 150-200 years now. We made progress.

I don’t like having to wash a print for such a long period of time, or deal with curling either. The amount of water needed for fiber is significantly more than RC.

What is the difference between CB Fiber Paper and NB Fiber Paper as B&H Photo sells both and does not explain the difference? Many thx.